تعمل مضخات المياه المدفوعة بالهواء على استغلال قوة الهواء لنقل المياه بكفاءة. تعتمد هذه المضخات على الهواء المضغوط لإنشاء ضغط يدفع المياه عبر النظام. ستجدها ضرورية في ديناميات السوائل بسبب قدرتها على التعامل مع تطبيقات متنوعة. تصميمها المبتكر يجعلها حلاً موثوقًا للعديد من الصناعات.

قوة الهواء في ضخ المياه

كيف يدفع ضغط الهواء عملية الضخ

يلعب ضغط الهواء دورًا مركزيًا في تشغيل مضخات المياه المدفوعة بالهواء. عندما يدخل الهواء المضغوط إلى نظام المضخة، فإنه يخلق قوة تدفع المياه عبر المضخة. تعتمد هذه العملية على الفرق في الضغط بين الهواء والماء. يجبر ضغط الهواء العالي المياه على التحرك من مناطق الضغط المنخفض إلى الضغط العالي، مما يضمن تدفقًا ثابتًا. من خلال استغلال قوة الهواء، يمكن لهذه المضخات نقل المياه بكفاءة دون الاعتماد على الكهرباء أو المحركات الميكانيكية.

شرح خطوة بخطوة لآلية العمل

فهم كيفية عمل هذه المضخات يمكن أن يساعدك في تقدير بساطتها. إليك تحليل خطوة بخطوة:

- يدخل الهواء المضغوط إلى غرفة المضخة.

- يدفع ضغط الهواء ضد غشاء أو مكبس داخل الغرفة.

- هذه الحركة تخلق شفطًا، مما يجذب الماء إلى المضخة.

- تتحكم الصمامات في التدفق، مما يضمن حركة الماء في اتجاه واحد.

- يخرج الماء من خلال مخرج التصريف، مما يكمل الدورة.

يبرز هذا الميكانيزم البسيط سبب كون المضخات المدفوعة بالهواء موثوقة للغاية.

المبادئ الأساسية لمضخات المياه المدفوعة بالهواء

هناك ثلاثة مبادئ رئيسية تحكم تشغيل هذه المضخات:

- فرق الضغط: تعتمد المضخة على الاختلافات في ضغط الهواء والماء للعمل.

- ضغط الهواء: الهواء المضغوط يوفر الطاقة اللازمة لنقل الماء

- التحكم في التدفق: الصمامات والخامات تضمن حركة الماء بسلاسة ومسيطرة.

توضح هذه المبادئ كيف أن قوة الهواء تدفع العملية بأكملها، مما يجعل هذه المضخات فعالة ومتعددة الاستخدامات.

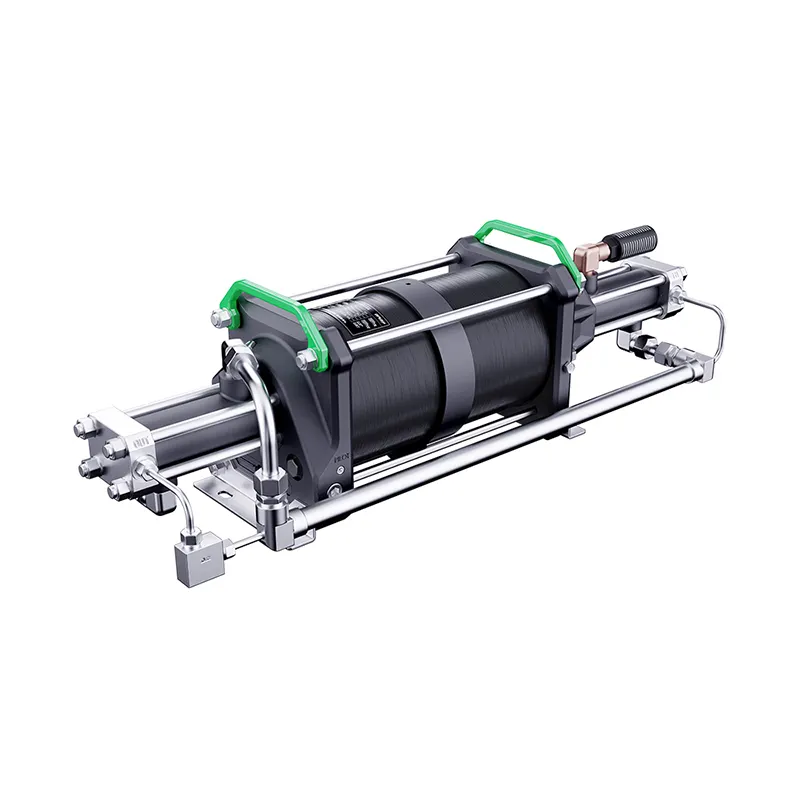

مكونات مضخات المياه المدفوعة بالهواء

يعمل ضاغط الهواء كقلب مضخة المياه التي تعمل بالهواء. إنه يولد الهواء المضغوط اللازم لتشغيل النظام. من خلال ضغط الهواء إلى ضغط عالٍ، يوفر الطاقة المطلوبة لتحريك المياه عبر المضخة. يمكنك أن تفكر فيه كالمحرك الذي يدفع العملية بأكملها. بدون ضاغط هواء موثوق، لا يمكن أن تعمل المضخة بفعالية. يضمن الصيانة الدورية للضاغط أداءً متسقًا ويمنع الانقطاعات في التشغيل.

غرفة المضخة هي المكان الذي تحدث فيه السحر. هذه المساحة المغلقة تحتفظ بالمياه والهواء المضغوط أثناء عملية الضخ. داخل الغرفة، يلعب الحجاب الحاجز دورًا حاسمًا. يتحرك الحجاب الحاجز ذهابًا وإيابًا مع تغير ضغط الهواء، مما يخلق شفطًا لجذب المياه ثم دفعها للخارج. يضمن هذا الحركة تدفقًا سلسًا ومستمرًا للمياه. ستجد أن الحجاب الحاجز غالبًا ما يصنع من مواد متينة لتحمل التآكل مع مرور الوقت.

تتحكم الصمامات والختمات في اتجاه وتدفق الماء داخل المضخة. تضمن صمامات الفحص تدفق الماء في اتجاه واحد، مما يمنع التدفق العكسي. تحافظ الختمات على نظام محكم، مما يحافظ على الضغط اللازم للتشغيل الفعال. أخيرًا، يطلق مخرج التصريف الماء بعد ضخه. تعمل هذه المكونات معًا بتناغم لتوفير تدفق ماء موثوق ومتحكم فيه. إن العناية المناسبة بهذه الأجزاء تطيل عمر مضختك وتضمن أداءً مثاليًا.

فوائد مضخات الماء المدفوعة بالهواء

تقدم مضخات الماء المدفوعة بالهواء كفاءة طاقة ملحوظة. تعتمد هذه المضخات على الهواء المضغوط بدلاً من الكهرباء أو المحركات التي تعمل بالوقود. يقلل هذا التصميم من استهلاك الطاقة، خاصة في العمليات التي يتم فيها استخدام ضواغط الهواء بالفعل. يمكنك توفير تكاليف الطاقة من خلال دمج هذه المضخات في نظامك. بالإضافة إلى ذلك، فإن بساطة آليتها تقلل من فقدان الطاقة أثناء التشغيل.

واحدة من الميزات البارزة لمضخات المياه المدفوعة بالهواء هي تعدد استخداماتها. يمكن لهذه المضخات التعامل مع مجموعة واسعة من السوائل، بما في ذلك الماء والمواد الكيميائية والسوائل اللزجة. تصميمها يسمح لها بالعمل بفعالية في بيئات متنوعة، من المصانع الصناعية إلى الحقول الزراعية. يمكنك استخدامها في التطبيقات التي تتطلب الدقة، مثل جرعات المواد الكيميائية، أو للمهام الثقيلة مثل إدارة مياه الصرف الصحي. هذه القابلية للتكيف تجعلها أداة قيمة عبر صناعات متعددة.

الخاتمة

تجمع مضخات المياه المدفوعة بالهواء بين البساطة والكفاءة. لقد تعلمت كيف أن الهواء المضغوط يشغل عملياتها وكيف أن مكونات مثل الأغشية والصمامات تضمن أداءً سلسًا. توفرها في استهلاك الطاقة، ومتانتها، وتعدد استخداماتها تجعلها مثالية لتطبيقات متنوعة. استكشف هذه المضخات لتلبية احتياجاتك أو استشر خبيرًا للعثور على الخيار المثالي.