Air driven hydraulic pumps rely on the strength of air to perform efficiently. Understanding their components and working mechanism helps you appreciate their functionality and benefits.

Components of Air Driven Hydraulic Pumps

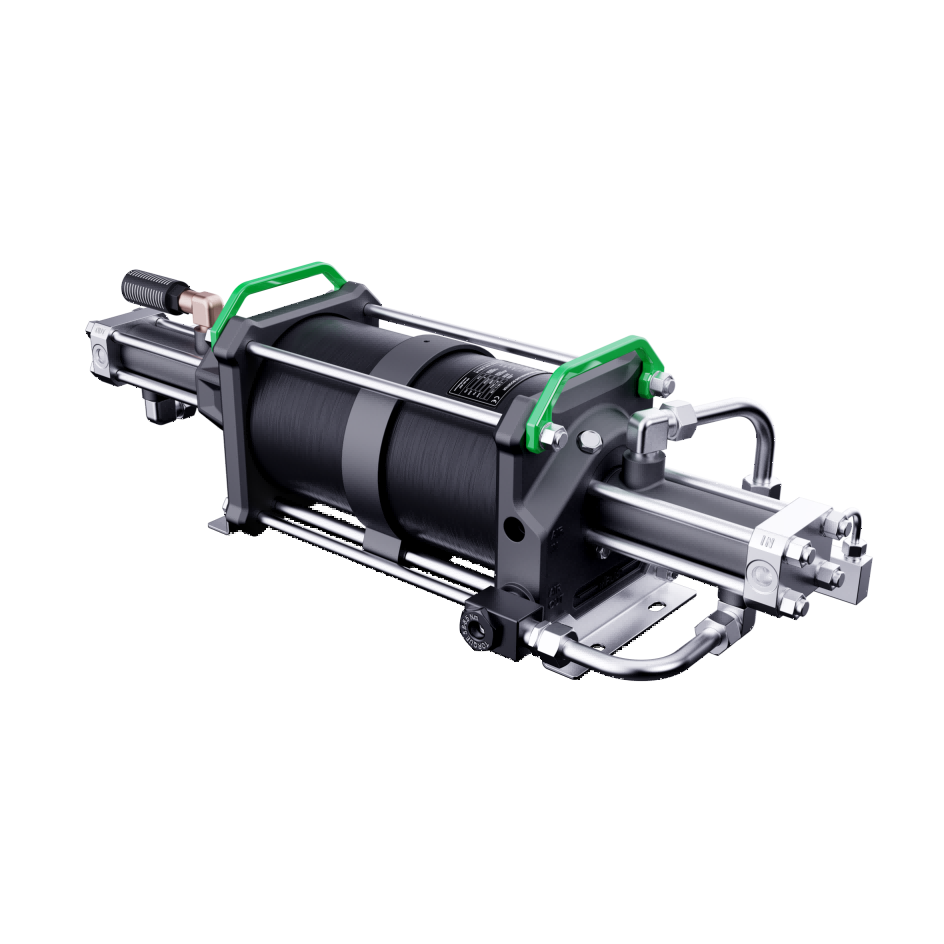

Air Compressor: The air compressor serves as the heart of the system. It compresses air, which provides the necessary force to drive the hydraulic pump. You will find that the strength of air generated by the compressor is crucial for the pump's operation.

Hydraulic Cylinder: This component converts the compressed air into hydraulic energy. The hydraulic cylinder uses the strength of air to move pistons, creating the pressure needed to perform various tasks.

Control Valves: Control valves regulate the flow of air and hydraulic fluid within the system. They ensure that the pump operates smoothly and efficiently. By adjusting these valves, you can control the output and maintain the desired pressure levels.

Working Mechanism

Conversion of Air Pressure to Hydraulic Power: The pump converts air pressure into hydraulic power through a series of mechanical processes. The air compressor generates high-pressure air, which then moves the pistons in the hydraulic cylinder. This movement creates hydraulic pressure, which powers the system.

Regulation and Control of Output: You can regulate and control the output of the pump using control valves. These valves allow you to adjust the flow and pressure of the hydraulic fluid. This precise control ensures that the pump delivers consistent performance, even in demanding applications.

By understanding these components and mechanisms, you can see how the strength of air plays a vital role in the operation of air driven hydraulic pumps. This knowledge helps you make informed decisions when choosing and using these pumps in various applications.

Advantages of Air Driven Hydraulic Pumps

Air driven hydraulic pumps offer numerous benefits that make them a preferred choice in various industries. By understanding these advantages, you can make informed decisions about incorporating this technology into your operations.

Efficiency and Energy Savings

Reduced Energy Consumption: Air driven hydraulic pumps excel in energy efficiency. They utilize the strength of air to generate hydraulic power without relying on electricity. This feature significantly reduces energy consumption, making them an environmentally friendly option. You can achieve substantial energy savings by opting for these pumps.

Lower Operational Costs: The reduced energy consumption directly translates to lower operational costs. You save money on energy bills and maintenance expenses. The simplicity of air driven systems minimizes wear and tear, reducing the need for frequent repairs. This cost-effectiveness makes them an attractive choice for businesses looking to optimize their budgets.

Precision and Control

Accurate Pressure Regulation: Air driven hydraulic pumps provide precise control over pressure levels. You can easily adjust the output to meet specific requirements. This accuracy ensures that the pump delivers consistent performance, even in demanding applications. The strength of air allows for fine-tuning, enhancing the overall efficiency of your operations.

Enhanced Performance in Delicate Operations: These pumps excel in delicate operations where precision is crucial. The ability to regulate pressure accurately ensures that sensitive tasks are performed with care. You can rely on air driven hydraulic pumps to handle intricate processes without compromising quality or safety.

Versatility and Adaptability

Wide Range of Applications: The versatility of air driven hydraulic pumps makes them suitable for a wide range of applications. From manufacturing to automotive industries, these pumps deliver reliable performance. You can use them in various settings, benefiting from their adaptability and strength of air.

Easy Integration with Existing Systems: Air driven hydraulic pumps integrate seamlessly with existing systems. Their compact design and lightweight nature facilitate easy installation. You can incorporate them into your operations without significant modifications. This adaptability ensures that you can enhance your systems efficiently and effectively.

By leveraging the strength of air, air driven hydraulic pumps provide efficiency, precision, and versatility. These advantages make them a valuable asset in diverse industrial applications. You can optimize your operations and achieve superior results by choosing this innovative technology.

Applications of Air Driven Hydraulic Pumps

Air driven hydraulic pumps find their place in a variety of applications, showcasing their versatility and adaptability. You will discover their utility in both industrial and specialized settings, where the strength of air plays a crucial role in enhancing performance and efficiency.

Industrial Applications

Manufacturing and Assembly Lines

In manufacturing and assembly lines, air driven hydraulic pumps provide reliable power. You can use them to operate machinery and equipment efficiently. Their ability to deliver consistent pressure ensures smooth operations, reducing downtime and increasing productivity. The strength of air allows these pumps to handle demanding tasks with ease, making them an essential component in modern manufacturing processes.

Automotive Industry

The automotive industry benefits greatly from air driven hydraulic pumps. You can rely on them for tasks such as lifting, pressing, and forming components. Their precision and control make them ideal for delicate operations, ensuring high-quality results. By integrating these pumps into your automotive processes, you enhance efficiency and maintain the highest standards of production.

Specialized Uses

Aerospace and Defense

In aerospace and defense, precision and reliability are paramount. Air driven hydraulic pumps excel in these fields, providing the necessary power for critical applications. You can trust them to perform under extreme conditions, where the strength of air ensures consistent and dependable operation. Their compact design and lightweight nature make them suitable for use in aircraft and military vehicles, where space and weight are at a premium.

Medical Equipment

Air driven hydraulic pumps also play a vital role in the medical field. You can find them in equipment that requires precise control and gentle handling, such as patient lifts and surgical tools. Their ability to regulate pressure accurately ensures safe and effective operation, protecting both patients and healthcare professionals. By choosing air driven hydraulic pumps for medical applications, you prioritize safety and reliability.

These applications highlight the diverse capabilities of air driven hydraulic pumps. By leveraging the strength of air, you can optimize performance across various industries, ensuring efficient and effective operations.

Air driven hydraulic pumps offer significant advantages that enhance your operations. You benefit from reduced energy consumption, precise control, and versatile applications. The strength of air ensures efficient performance across various industries. By adopting this technology, you optimize processes and achieve superior results. Embrace air driven hydraulic pumps to elevate your industrial capabilities and maintain a competitive edge.