Luftbetriebene Hydraulikpumpen verbessern die Sicherheit in industriellen Umgebungen. Sie können sich auf ihr Design verlassen, um Risiken in gefährlichen Bereichen zu minimieren. Diese Pumpen arbeiten ohne Funken, was sie ideal für explosive Umgebungen macht. Ihre Zuverlässigkeit reduziert Ausfälle von Geräten, was hilft, Unfälle zu verhindern. Durch die Verwendung dieser Pumpen stellen Sie die Einhaltung strenger Sicherheitsstandards sicher und schützen die Arbeiter.

Betriebsprinzipien von luftbetriebenen Hydraulikpumpen

Druckluft treibt hydraulische Systeme an, indem sie pneumatische Energie in hydraulischen Druck umwandelt. Sie beginnen, indem Sie der Pumpe Druckluft zuführen. Die Pumpe nutzt dann diese Luft, um einen Kolben zu bewegen, der die Hydraulikflüssigkeit unter Druck setzt. Diese unter Druck stehende Flüssigkeit treibt verschiedene industrielle Werkzeuge und Maschinen an. Der Prozess beseitigt die Notwendigkeit für Elektrizität, was es sicherer in Umgebungen mit brennbaren Materialien macht. Sie können sich auf dieses System verlassen, um auch unter extremen Bedingungen eine konstante Leistung zu liefern.

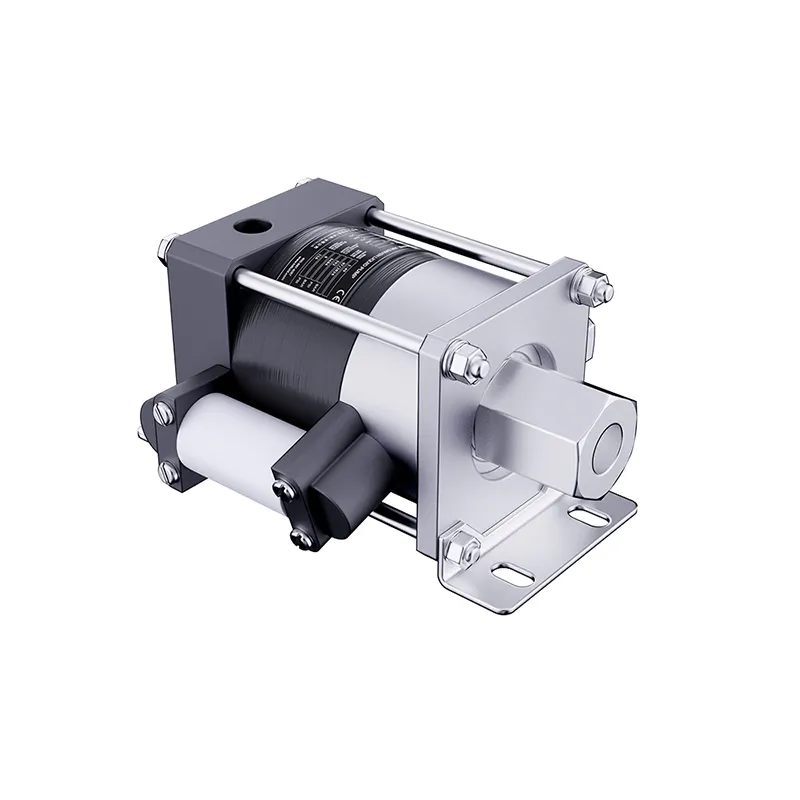

Luftbetriebene Hydraulikpumpen bestehen aus mehreren kritischen Komponenten. Der Luftmotor treibt die Pumpe an, ohne Funken zu erzeugen, was das Brandrisiko verringert. Der hydraulische Kolben sorgt für eine präzise Druckregelung und verhindert Überlastung. Dichtungen und Ventile verhindern Leckagen und halten gefährliche Flüssigkeiten eingeschlossen. Diese Komponenten arbeiten zusammen, um Sicherheit und Zuverlässigkeit zu erhöhen. Sie können diesen Pumpen vertrauen, dass sie effizient arbeiten und gleichzeitig Risiken minimieren.

Druckluft bietet mehrere Vorteile gegenüber elektrischen Systemen. Luftbetriebene Pumpen erzeugen keine Wärme oder Funken, was sie ideal für explosive Umgebungen macht. Sie sind leicht und tragbar, sodass Sie sie in abgelegenen oder engen Räumen verwenden können. Im Gegensatz zu elektrischen Systemen können sie sicher in nassen oder korrosiven Bedingungen betrieben werden. Durch die Wahl von luftbetriebenen Hydraulikpumpen stellen Sie sicher, dass die Betriebsabläufe in herausfordernden industriellen Umgebungen sicherer und anpassungsfähiger sind.

Sicherheitsmerkmale von luftbetriebenen Hydraulikpumpen

Druckregelung und Überlastschutz

Luftbetriebene Hydraulikpumpen enthalten integrierte Druckregelungssysteme. Diese Systeme stellen sicher, dass die Pumpe innerhalb sicherer Druckgrenzen arbeitet. Wenn der Druck den festgelegten Schwellenwert überschreitet, passt die Pumpe automatisch an oder schaltet sich ab, um Schäden zu vermeiden. Diese Funktion schützt sowohl die Ausrüstung als auch den Bediener. Überlastschutzmechanismen spielen ebenfalls eine entscheidende Rolle. Sie verhindern, dass die Pumpe überarbeitet wird, was das Risiko von Überhitzung oder mechanischem Versagen verringert. Sie können sich auf diese Funktionen verlassen, um sichere und effiziente Abläufe in anspruchsvollen Umgebungen aufrechtzuerhalten.

Leckverhinderungs- und Eindämmungsmechanismen

Lecks in hydraulischen Systemen können zu gefährlichen Situationen führen. Luftbetriebene Hydraulikpumpen gehen dieses Problem mit fortschrittlichen Dichtungstechnologien an. Hochwertige Dichtungen und Ventile verhindern, dass Hydraulikflüssigkeit entweicht. Diese Eindämmung verringert das Risiko der Exposition gegenüber giftigen oder brennbaren Substanzen. Darüber hinaus minimiert das Design die Chancen einer Umweltverschmutzung. Durch die Verwendung dieser Pumpen gewährleisten Sie einen sichereren Arbeitsplatz und erfüllen die Umwelt- und Sicherheitsstandards.

Trockenlauf-Fähigkeiten für gefährliche Umgebungen

Trockenlauf tritt auf, wenn eine Pumpe ohne Hydraulikflüssigkeit arbeitet. Viele Pumpen versagen unter diesen Bedingungen, aber luftbetriebene Hydraulikpumpen sind dafür ausgelegt, damit umzugehen. Ihr luftbetriebenes Mechanismus verhindert Schäden während des Trockenlaufs. Diese Fähigkeit macht sie ideal für gefährliche Umgebungen, in denen sich die Flüssigkeitsstände ändern können. Sie können diesen Pumpen vertrauen, dass sie auch unter herausfordernden Bedingungen sicher weiterarbeiten.

Praktische Sicherheitsvorteile in industriellen Anwendungen

Luftbetriebene Hydraulikpumpen bieten ein einzigartiges Sicherheitsmerkmal, das als "Dead-Head"-Betrieb bekannt ist. Das bedeutet, dass die Pumpe aufhören kann zu arbeiten, wenn der Ausgangsfluss blockiert ist, ohne Schäden oder Überhitzung zu verursachen. Sie können sich auf dieses Merkmal verlassen, um Risiken in Hochdrucksystemen zu reduzieren. Es verhindert Ausfälle von Geräten und minimiert die Wahrscheinlichkeit von Unfällen. Diese Fähigkeit stellt sicher, dass die Pumpe auch bei unerwarteten Unterbrechungen sicher und funktionsfähig bleibt. Durch die Verwendung dieser Pumpen schaffen Sie eine sicherere Arbeitsumgebung für die Bediener und reduzieren Ausfallzeiten, die durch Gerätefehler verursacht werden.

Das leichte Design der luftbetriebenen Hydraulikpumpen macht sie einfach zu transportieren. Sie können sie zwischen den Arbeitsplätzen bewegen oder in engen Räumen ohne Schwierigkeiten verwenden. Ihre Anpassungsfähigkeit ermöglicht es Ihnen, sie in verschiedenen gefährlichen Umgebungen zu betreiben, wie z. B. in Bereichen mit brennbaren Gasen oder korrosiven Materialien. Diese Pumpen sind nicht auf Elektrizität angewiesen, sodass sie in nassen oder explosiven Bedingungen sicher bleiben. Ihre Portabilität und Vielseitigkeit machen sie zu einer ausgezeichneten Wahl für Branchen, die flexible und zuverlässige Ausrüstung benötigen.

Luftbetriebene Hydraulikpumpen sind so konzipiert, dass sie strengen Sicherheitsstandards entsprechen. Viele Modelle verfügen über Zertifizierungen, die ihre Konformität mit den Branchenvorschriften nachweisen. Sie können diesen Zertifizierungen vertrauen, um sicherzustellen, dass die Pumpen für den Einsatz in gefährlichen Umgebungen sicher sind. Durch die Wahl zertifizierter Geräte zeigen Sie ein Engagement für die Sicherheit am Arbeitsplatz und die Einhaltung von Vorschriften. Dies schützt nicht nur die Arbeiter, sondern hilft Ihnen auch, Strafen wegen Nichteinhaltung zu vermeiden. In diese Pumpen zu investieren zeigt, dass Sicherheit in Ihren Abläufen oberste Priorität hat.

Schlussfolgerung

Luftbetriebene Hydraulikpumpen spielen eine entscheidende Rolle bei der Gewährleistung der Sicherheit in industriellen Umgebungen. Ihr innovatives Design reduziert Risiken und sorgt für zuverlässige Leistung. Sie können sich auf diese Pumpen verlassen, um strenge Sicherheitsstandards zu erfüllen und gleichzeitig Arbeiter und Ausrüstung zu schützen. Die Priorisierung dieser Pumpen in Ihren Abläufen zeigt ein Engagement für Sicherheit und betriebliche Exzellenz.