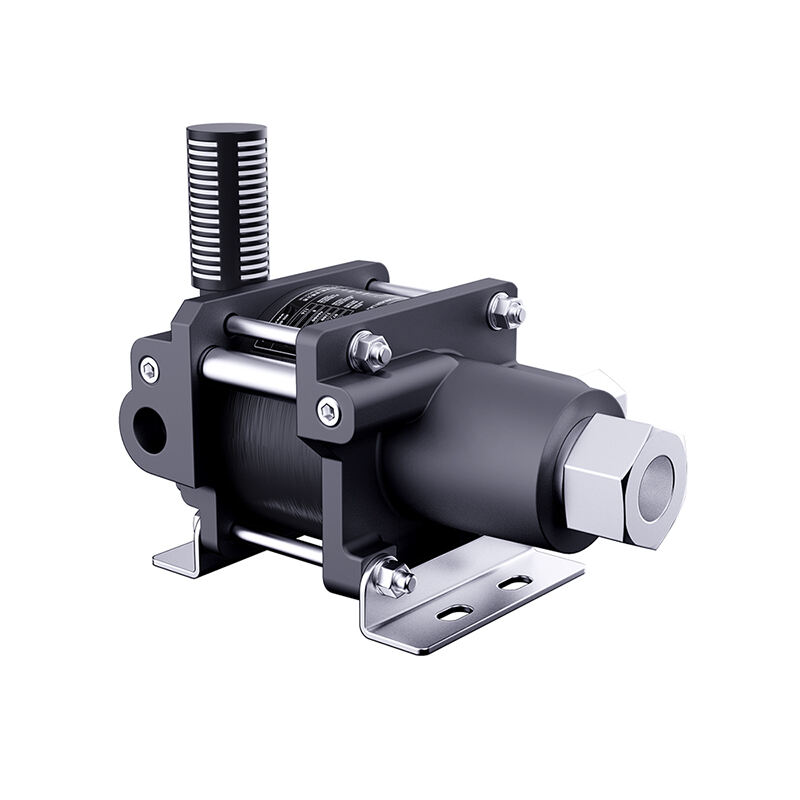

air driven

The air driven is a sophisticated piece of technology designed to harness the power of compressed air to drive various mechanical applications. Its main functions include providing motive power for tools and machinery, as well as generating precise control for automated systems. Technological features of the air driven include its compact design, high efficiency, and low maintenance requirements. It operates without the need for complex electrical systems, making it ideal for environments where electrical hazards are a concern. The air driven finds applications across various industries such as automotive, manufacturing, and construction, where it is used in tools like impact wrenches, grinders, and sanders. Its versatility makes it an indispensable component in many industrial settings, improving productivity and safety.